A comprehensive range, international certifications

Complete range, international certifications

Precision, versatility, and durability: these are the principles that guide Gadinox production.

Thanks to decades of experience in processing stainless steel and nickel alloys, we manufacture critical and structural components for complex industrial plants, adhering to the highest international standards.

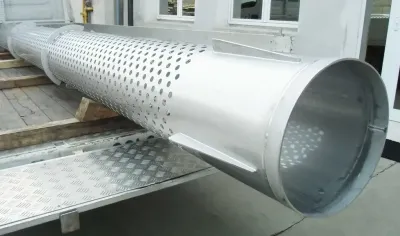

The product range covers a wide variety of elements - pipes, bends, fittings, tanks, pressure vessels, columns, filters, and exchangers - all manufactured in-house and tested according to the PED directive and the ASME code.

Each component can be customized upon request in terms of dimensions, materials, thicknesses, finishes, and accessories.

Our production facility, equipped with dedicated lines and advanced equipment, allows us to handle both single orders and series production with speed, reliability, and certified quality control. This means meeting agreed-upon delivery times while maintaining the required quality.

Here's a summary of our production:

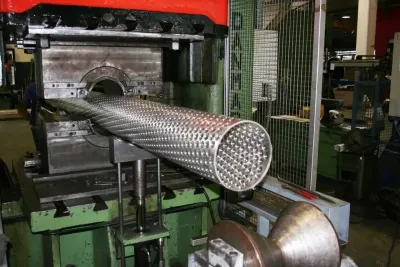

- Tubes (circular, square, and rectangular cross-sections) in stainless steel, duplex, super-duplex, and nickel alloys, compliant with ASTM A312/A358/A790/A928. Diameters from 20 to 3000 mm (3/4" to 120"), wall thicknesses from 2 to 100 mm, lengths up to 20 m.

- Stamped and segmented bends compliant with ANSI B16.9/ASTM A403, with variable radii (≤1.5D, 1D, large radius).

- Shaped tees, collars, tapered reducers, rolled rings, and custom tanks.

- Pressure vessels certified to PED 2014/68/EU and ASME VIII Div 1.

- Vacuum chambers, shell and tube exchangers, distillation columns, filter dryers, mixers, and dissolvers.

- Bonus: Complex machining available upon request.